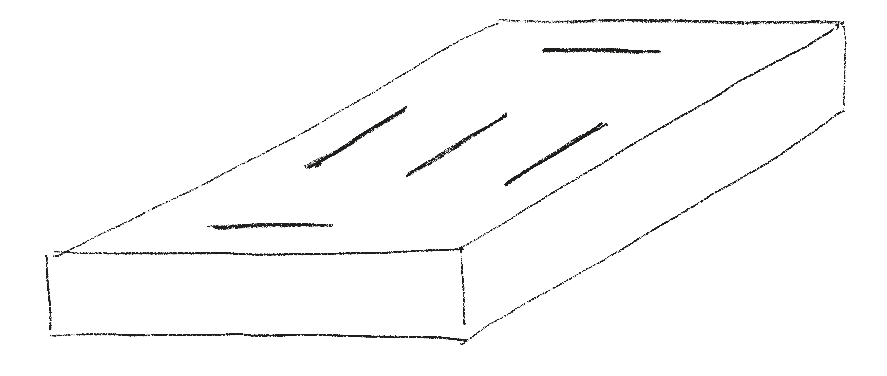

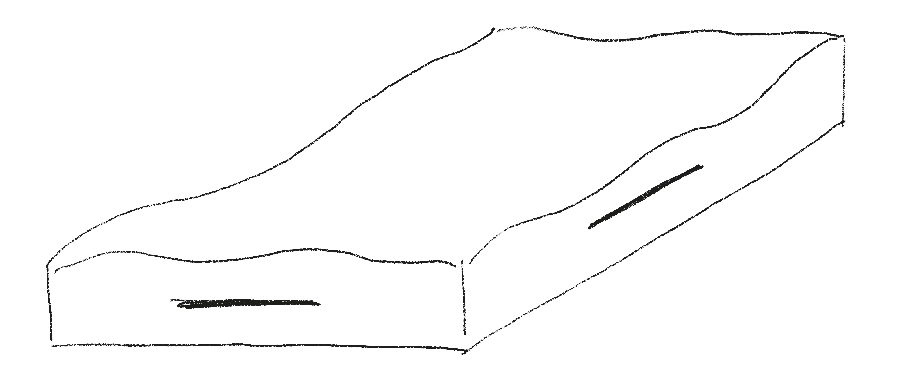

Profile groove for Clamex-P connector

... on the CNC machine

P-System

The P-System from Lamello is an innovative, award-winning joining method. With the Clamex, Tenso, and Divario connecting elements, the overall process of design, manufacturing, transport, and assembly is more flexible, faster, and simpler than ever before.

The installation or anchoring of the connector itself is based on the P-System profile groove. The profile groove can be milled using modern CNC technology. Aggregates can get around the space limitations of the machine and allow use of the Clamex connector. Different aggregate solutions are possible for different applications.

MONO FUNCTION LINE - Angle head with profile cutter

VARIO CLASSIC SMART LINE - Angle aggregate with simple angle adjustment

SOFT TOUCH PRO HORI FUNCTION LINE - Floating aggregate for sawing

SOFT TOUCH PRO FUNCTION LINE - floating aggregate with profile milling cutter

Aggregate solutions for milling P-System profile grooves using CNC technology

Standard aggregates such as the MONO, DUO, or QUATTRO FUNCTION LINE allow the profile groove to be positioned at any point on the board thanks to the vertical position of the Clamex groove side milling cutter.

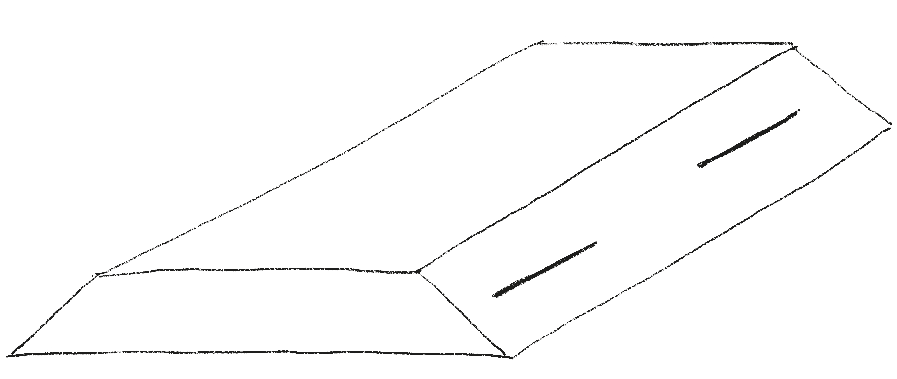

For diagonal positioning of the groove, the MONO FIX FUNCTION LINE (fixed angle) or the VARIO (variable angle) aggregate can be used. The grooving cutter tool of the respective aggregate is plunged into the surface during machining and moved sideways at a precise depth.

Aggregate solutions for surfaces with thickness fluctuations

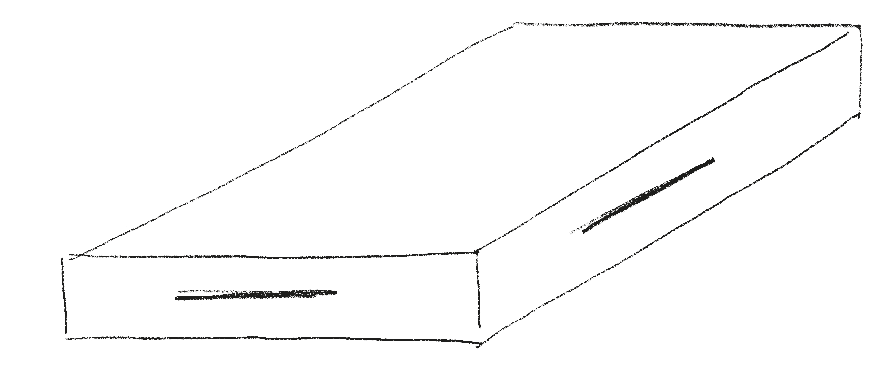

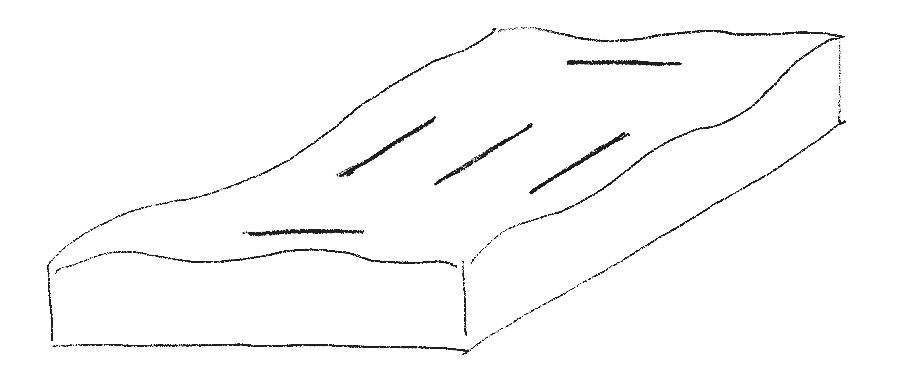

Profile grooves for the P-System can also be milled with constant and defined positioning into edges and faces of workpieces that have thickness fluctuations.

The SOFT TOUCH PRO FUNCTION LINE, which is equipped with a special floating bell, is suitable for this type of machining.

|

Profile grooves in surfaces (middle and near-edge regions) |

Profile grooves in edges |

Profile grooves in miters |

Profile grooves in surfaces with thickness fluctuations (Middle and near-edge regions) |

Profile grooves in edges with thickness fluctuations |

|

|

|

|

|

|

|

|

3-AXIS MACHINE The machine can move along three axes: |

• One aggregate mills the profile groove in one axis direction (X or Y). |

Groove cutter with spindle |

• One aggregate mills the profile groove in one side of the miter. |

SOFT TOUCH PRO HORI FUNCTION LINE • One aggregate mills the profile groove with surface probing in one axis direction (X or Y). |

|

|

4-AXIS MACHINE The machine moves like a 3-axis machine does but also has the ability, e.g., to rotate an aggregate by 360° about the Z-axis. This allows, e.g., Clamex P to be introduced at 0° and 90° without the need for reclamping. |

One aggregate for producing profile grooves in the X and Y axis directions. |

Groove cutter with spindle |

One aggregate for producing profile grooves in the X and Y axis directions. |

SOFT TOUCH PRO HORI FUNCTION LINE One aggregate for producing profile grooves in the X and Y axis directions with surface probing. |

SOFT TOUCH PRO HORI FUNCTION LINE One aggregate for producing profile grooves in edges with surface probing. |

|

5-AXIS MACHINE The machine moves like a 4-axis machine does but can also swivel the spindle to perform machining in other dimensions. |

One aggregate for producing profile grooves in the X and Y axis directions. |

Groove cutter with spindle |

Groove cutter with spindle |

SOFT TOUCH PRO HORI FUNCTION LINE One aggregate for producing profile grooves |

SOFT TOUCH PRO HORI FUNCTION LINE One aggregate for producing profile grooves |

Clamex P Profilnut mit Tastaggregat in die Kante

Clamex P Profilnut mit Winkelaggregat in die Fläche

FAQ Fragen zur Clamex P Profilnut

To avoid the collision with the motor spindle, a compact angle head with a horizontal tool spindle is used in the machine. The groove cutter is then vertical to the machining surface and can introduce the groove in the middle of the surface with a high process reliability.

Depending on the specific aggregate used, up to four tools may be mounted. The DUO FUNCTION LINE has two and the QUATTRO FUNCTION LINE has four tool outputs. These aggregates, depending on their interference contours, can save considerable space in the tool changer and time in the production process.

Thanks to its compact housing, the VARIO CLASSIC SMART LINE can mill Clamex P profile grooves at different angles as well as in surfaces (middle and near-edge regions) and edges.

ATEMAG aggregates are available with different numbers of tool outputs. With a QUATTRO FUNCTION LINE (four outputs), for example, three more tool outputs can be used for routing, drilling, or sawing.

The DUO FUNCTION LINE (two outputs) enables another drilling or routing tool or a saw to be clamped into the second tool output. Integrated into the production process, this saves time by eliminating the need for tool change and also increases the capacity of the changer itself.

If the angle head is equipped with a modular spindle, clamps or saw spindles already holding tools can easily and quickly be exchanged as adapters.

Use of an aggregate in combination with the groove cutter (P-System) makes economic sense for automatic and precise milling of profile grooves for certain parts volumes. The aggregate improves the efficiency and precision of the CNC machine and reduces the machining time. In addition, use of an aggregate creates new machining possibilities.

For machining a workpiece with thickness fluctuations or compensating for clamping unevenness, a floating aggregate is needed. By constantly probing the reference surface, the floating aggregate can maintain a constant, defined machining depth over the entire workpiece and maintain the positioning of the milling tool with respect to the workpiece.

There are a number of different machine concepts from different machine manufacturers for milling grooves for Clamex P connectors. The P-System can be machined on console machines and flat table machines (nesting), compact machines (vertical or horizontal) on production lines, and numerous other machine types.

The cutting values for tools are generally made up of the parameters of rotational speed and feed rate.

These parameters are specified by the tool manufacturer.

Lamello has various partners that deliver tools. Either contact Lamello directly or contact a tool supplier that offers tools specifically for the Clamex Lamello groove.

Yes. Because the 3-axis machine only moves in three axis directions (X, Y, and Z), the Clamex P profile groove can only be milled in one axis direction. For milling profile grooves in the X and Y directions, an additional axis position is necessary. For this, a second aggregate with the required tool spindle axis orientation can be used.

Yes. The 4-axis machine enables rotation of the aggregate about the C-axis in addition to movements along the X-axis, Y-axis, and Z-axis. This allows milling of the Clamex P groove either along the X or the Y axis or at any intermediate angle.

FAQ Questions about drilling holes for Cabineo connectors on the CNC

The VERTINEO FUNCTION LINE multispindle aggregate can be used to drill three Cabineo holes in just one machining step for considerable time savings in the production process.

The holes are drilled with a constant axial spacing to produce the precise hole pattern required for insertion of the Cabineo connectors without the use of additional tools.

A “clean” hole pattern without tear-outs is produced when high-quality tools that ensure a precise hole pattern with the required triple holes are used.

FAQ general questions about CNC aggregates from ATEMAG

Yes, the CNC aggregates from ATEMAG can be used on nearly all CNC machines. For the appropriate connection of the aggregate to the motor spindle of the machine, the information about the machine connection and the appropriate torque arm with locating pins is required. The CNC aggregates are built using this information. Incidentally, aggregates can also be converted for use in other machines.

ATEMAG aggregates feature a modular design. The main advantage of this is that the aggregates can be adapted individually at any time, not just when they are purchased new. Subsequent adaptation to different CNC machines is easily possible because the torque arm and the machine connection can be flexibly swapped out.

With the product finder at www.atemag.de, you can find a standard aggregate that is suitable for your application. You can select the material to be machined and the machining method – the aggregate options are then filtered and suitable aggregates are displayed.

You can also email your queries to us or get advice over the phone

(+49-7832-9997-0 outside Germany or 07832-9997-0 within Germany).

Yes, ATEMAG aggregates can be used on all types of wood and wood-based materials. The important thing is that the right aggregate is selected in each case. We would be happy to advise you!

Yes, aggregates can be used with robots and CNC machines alike.

Any aggregate that needs to be repaired after a collision is checked for possible damage and wear by one of our mechanics. Defective aggregate parts are replaced, all wear parts are regreased or reoiled, and the interior of the aggregate is cleaned. If we find that repair would not be economically feasible, we offer you a new aggregate for purchase.

ATEMAG has been on the market since 2004 and is very proud of its history and the promise of quality it has kept from the very first day on. We have repaired ATEMAG aggregates that were made in the first two or three years of the company’s existence. This shows that with ideal machine processes and good care of the aggregates, a high aggregate quality is a guarantee of a long service life. With our extensive spare parts warehouse, we can repair almost any aggregate, but we also offer a new aggregate in exchange if repair is not economically feasible.

FAQ general questions about ATEMAG

We can deliver to anywhere in the world and offer technical support irrespective of location. The ATEMAG team is international and speaks German, English, Italian, Polish, Spanish, and other languages. We also have a worldwide network of dealers, whom we regularly qualify and who provide service locally.

Contact information can be found here:

https://www.atemag.de/kontakt.html

No. ATEMAG aggregates are sold directly through ATEMAG and through an extensive network of ATEMAG-trained dealers. Many well-known machine manufacturers, including Biesse, Felder, HolzHer, IMA, Masterwood, and Weinig, have been trusting in the ATEMAG quality and equipping their machines with ATEMAG aggregates for years.

We are a craft production facility and are specialized in developing and manufacturing high-quality aggregates. ATEMAG was founded in 2004 and has a wealth of experience in manufacturing aggregates, both single products and small series. By using modern manufacturing technologies and high-grade materials, we guarantee durable and precise aggregate solutions.

CNC aggregates that are manufactured by hand at the ATEMAG aggregate craft production facility display clear differences from aggregates that come off of industrial production lines. At ATEMAG, we pride ourselves on ensuring that all parts fit together perfectly. All bearings, gearwheels, and spacer rings are optimally coordinated. As a result, every aggregate is a one-of-a-kind.

Customer service is especially important to us and we focus on offering comprehensive advice and support in the selection and use of CNC aggregates. Each ATEMAG aggregate is a custom-made solution for individual requirements and is perfectly coordinated to the needs of the customer. The wide range of products offered encompasses angle heads, floating aggregates, multispindle aggregates, and special aggregates for various application areas, including routing, drilling, sawing, sanding, and more.

You can reach ATEMAG at any time via the homepage at www.atemag.de.

We work with dealers and partners around the world who have been trained by us and who can also provide in-depth technical information on the CNC aggregates in their respective languages. In addition, ATEMAG has a number of quality tool manufacturers as good and long-term partners who know the advantages of the angle heads and floating aggregates from ATEMAG and can provide information about them.