Hole drilling for Cabineo connector

... on the CNC machine

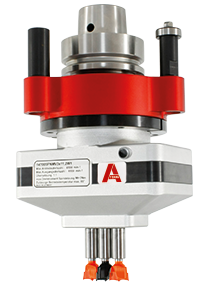

Drilling system for Cabineo connectors

The Cabineo is a one-piece connector based on drilling or milling for connecting bodies through pure surface machining.

Thanks to this property, machining can be done on all CNC machines, including

simple 3-axis machines and nesting machines.

The VERTINEO FUNCTION LINE drilling aggregate was developed especially for creating the recesses for Cabineo connectors and drills three holes with a precise, repeatable hole pattern in a single work step.

CNC aggregate specially designed for Cabineo connector drilling

|

3-AXIS MACHINE The machine can move along three axes: |

• Ein Aggregat bohrt das Cabineo Profil in einer Achsrichtung (X- oder Y-Achsrichtung). |

|

4-AXIS MACHINE The machine moves like a 3-axis machine does but also has the ability, e.g., to rotate an aggregate by 360° about the Z-axis. This allows, e.g., Clamex P to be introduced at 0° and 90° without the need for reclamping. |

Ein Aggregat bohrt das Cabineo Profil |

|

5-AXIS MACHINE The machine moves like a 4-axis machine does but can also swivel the spindle to perform machining in other dimensions. |

Ein Aggregat bohrt das Cabineo Profil |

| Download OVERVIEW | Download FLYER |

FAQ Questions about drilling holes for Cabineo connectors on the CNC

The VERTINEO FUNCTION LINE multispindle aggregate can be used to drill three Cabineo holes in just one machining step for considerable time savings in the production process.

The holes are drilled with a constant axial spacing to produce the precise hole pattern required for insertion of the Cabineo connectors without the use of additional tools.

A “clean” hole pattern without tear-outs is produced when high-quality tools that ensure a precise hole pattern with the required triple holes are used.

FAQ general questions about CNC aggregates from ATEMAG

Yes, the CNC aggregates from ATEMAG can be used on nearly all CNC machines. For the appropriate connection of the aggregate to the motor spindle of the machine, the information about the machine connection and the appropriate torque arm with locating pins is required. The CNC aggregates are built using this information. Incidentally, aggregates can also be converted for use in other machines.

ATEMAG aggregates feature a modular design. The main advantage of this is that the aggregates can be adapted individually at any time, not just when they are purchased new. Subsequent adaptation to different CNC machines is easily possible because the torque arm and the machine connection can be flexibly swapped out.

With the product finder at www.atemag.de, you can find a standard aggregate that is suitable for your application. You can select the material to be machined and the machining method – the aggregate options are then filtered and suitable aggregates are displayed.

You can also email your queries to us or get advice over the phone

(+49-7832-9997-0 outside Germany or 07832-9997-0 within Germany).

Yes, ATEMAG aggregates can be used on all types of wood and wood-based materials. The important thing is that the right aggregate is selected in each case. We would be happy to advise you!

Yes, aggregates can be used with robots and CNC machines alike.

Any aggregate that needs to be repaired after a collision is checked for possible damage and wear by one of our mechanics. Defective aggregate parts are replaced, all wear parts are regreased or reoiled, and the interior of the aggregate is cleaned. If we find that repair would not be economically feasible, we offer you a new aggregate for purchase.

ATEMAG has been on the market since 2004 and is very proud of its history and the promise of quality it has kept from the very first day on. We have repaired ATEMAG aggregates that were made in the first two or three years of the company’s existence. This shows that with ideal machine processes and good care of the aggregates, a high aggregate quality is a guarantee of a long service life. With our extensive spare parts warehouse, we can repair almost any aggregate, but we also offer a new aggregate in exchange if repair is not economically feasible.

FAQ general questions about ATEMAG

We can deliver to anywhere in the world and offer technical support irrespective of location. The ATEMAG team is international and speaks German, English, Italian, Polish, Spanish, and other languages. We also have a worldwide network of dealers, whom we regularly qualify and who provide service locally.

Contact information can be found here:

https://www.atemag.de/kontakt.html

No. ATEMAG aggregates are sold directly through ATEMAG and through an extensive network of ATEMAG-trained dealers. Many well-known machine manufacturers, including Biesse, Felder, HolzHer, IMA, Masterwood, and Weinig, have been trusting in the ATEMAG quality and equipping their machines with ATEMAG aggregates for years.

We are a craft production facility and are specialized in developing and manufacturing high-quality aggregates. ATEMAG was founded in 2004 and has a wealth of experience in manufacturing aggregates, both single products and small series. By using modern manufacturing technologies and high-grade materials, we guarantee durable and precise aggregate solutions.

CNC aggregates that are manufactured by hand at the ATEMAG aggregate craft production facility display clear differences from aggregates that come off of industrial production lines. At ATEMAG, we pride ourselves on ensuring that all parts fit together perfectly. All bearings, gearwheels, and spacer rings are optimally coordinated. As a result, every aggregate is a one-of-a-kind.

Customer service is especially important to us and we focus on offering comprehensive advice and support in the selection and use of CNC aggregates. Each ATEMAG aggregate is a custom-made solution for individual requirements and is perfectly coordinated to the needs of the customer. The wide range of products offered encompasses angle heads, floating aggregates, multispindle aggregates, and special aggregates for various application areas, including routing, drilling, sawing, sanding, and more.

You can reach ATEMAG at any time via the homepage at www.atemag.de.

We work with dealers and partners around the world who have been trained by us and who can also provide in-depth technical information on the CNC aggregates in their respective languages. In addition, ATEMAG has a number of quality tool manufacturers as good and long-term partners who know the advantages of the angle heads and floating aggregates from ATEMAG and can provide information about them.