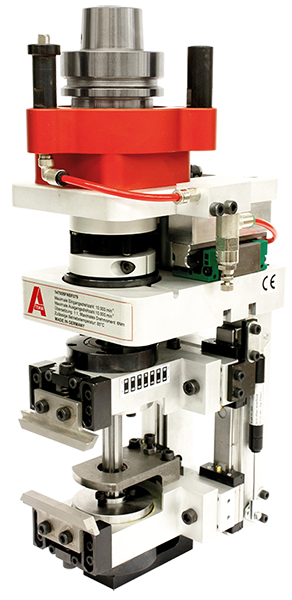

FLUSH TRIM ROUTING AGGREGATE FUNCTION LINE

Aggregate for milling of glued-on edge banding flush with board with probing function

Technical Data

| Machining options |  Milling |

|||

| Max. input speed: | 10.000 rpm | |||

| Max. output speed: | 10.000 rpm | |||

| Gear ratio: | 1 : 1 | |||

| Max. torque: | 6 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Positioning of torque arm with respect to tool: | 4 X 90° | |||

| Machining angle: | 90° | |||

| Number of tool outputs: | 2 / fix | |||

| Lubrication: | Grease / Lifetime lubrication | |||

| Compressed air is required on the machine side for the functions of the unit. | ||||

Simultaneous processing of both sides of the wooden panel

The flush trimming aggregate is primarily used in the edge finishing of panel materials. Here, protrusions of the glued edges are removed and a radius or chamfer is milled flush at the same time, resulting in a precise and even edge. This technique, known as flush milling of edges, is used for kitchen worktops or furniture elements, for example. Solid wood steps are also processed flush with the floating aggregate in staircase production. Thanks to the individual probing technology of the aggregate, edges can be probed and processed simultaneously and separately (from above and below). Both sides of the workpiece panel are copied individually and compensate for unevenness and thickness variations. The processing time is also considerably reduced by processing on both sides.

The flush milling aggregate works cost-effective and flexibility

By reducing the number of components and optimizing the design, ATEMAG has succeeded in making the flush milling aggregate more cost-effective. The savings are passed on directly to the customer, making the aggregate available at a more attractive price. Despite the cost reduction, the high quality and performance of the aggregate remains unchanged.

The standard version of the aggregate is equipped with a vertical feeler. An optional horizontal scanning of the edge is also available, which enables a probing range of ±2 mm. This flexibility allows an even greater variety of applications in different areas of woodworking. The improved flush trimming aggregate not only offers greater efficiency and precision, but also an attractive cost structure. Woodworking companies thus benefit from an advanced technology that both reduces production costs and increases the quality of the end products.

Panel processing: After gluing on the edge, the unit mills the edge protrusion flush with the top and bottom of the panel using the integrated touch function.

Tool connection

- Tool mounting 3x M4 on pitch circle Ø25, Centering diameter Ø19h5

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

Your request for the FLUSH TRIM ROUTING AGGREGATE FUNCTION LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use