EXTRA ZERO FUNCTION LINE

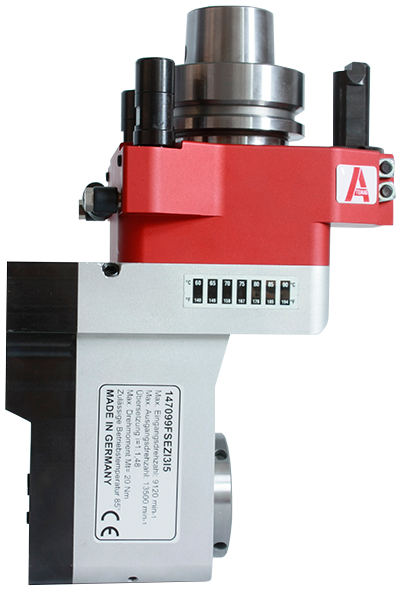

Lockset recess aggregate with two horizontal tool outputs specifically for lockset recess routing or baluster hole drilling Tool spindle is in axial alignment with the cone The design allows the use of long tools with a small interference circle diameter.

Technical Data

EXTRA ZERO FUNCTION LINE product flyer comming soon

| Machining options |  Drilling |

Milling |

||

| Max. input speed: | 9.120 rpm | |||

| Max. output speed: | 13.500 rpm | |||

| Gear ratio: | 1 : 1,48 | |||

| Max. torque: | 20 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Positioning of torque arm with respect to tool: | 4 x 90° | |||

| Machining angle: | 90° | |||

| Number of tool outputs: | 2 / fix | |||

| Lubrication: | Grease / Rota Lube – Lifetime lubrication | |||

Product Information

Machining capabilities: Drilling and routing

Typical applications:

- Doors: Lockset recess routing and forend routing in edges

- Stairs: Baluster hole drilling in stringer or railing

- Furniture making: Dowel hole drilling and drilling of holes for insert boards

- Drilling and milling operations even where space in the machine is limited.

- ...

Tool connection

- ER25 internal

- ER16 internal

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

Product images and videos

Your request for the EXTRA ZERO FUNCTION LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use