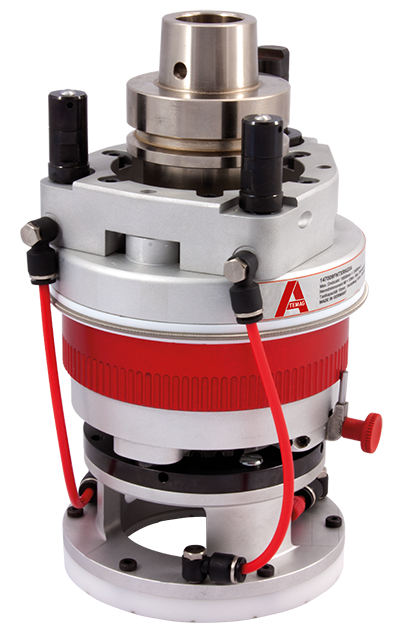

SOFT TOUCH PRO FUNCTION LINE

Floating aggregate for constant and defined machining depth despite clamping unevenness and thickness fluctuations

Technical Data

| Machining options |  Drilling |

Milling |

Sawing |

|

| Max. input speed: | 18.000 rpm | |||

| Max. output speed: | 18.000 rpm | |||

| Gear ratio: | 1 : 1 | |||

| Max. torque: | 10 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Machining angle: | 0° | |||

| Number of tool outputs: | 1 / fixed | |||

| Lubrication: | Grease / Lifetime lubrication | |||

| Floating capacity: | 10 mm | |||

| Adjustment range: | 10 mm | |||

| Setting precision: | 0,01 mm | |||

| Probing direction: | Axial | |||

Product Information

Machining options: Routing, drilling, grinding, profiling, and sawing with surface probing (vertical and horizontal) Diverse machining possibilities thanks to modular system allowing individual adaptation to different requirements.

Typical applications:

- Facade installation: Routing of V-grooves in ALUCOBOND

- Stairs: Edge machining of stair treads

- Furniture making: Clamex P connectors in edges

- Kitchens: Routing of recesses in countertops / doors: Decorative grooves

- Formwork installation: Drilling at a defined depth

- Automotive and aerospace: Edge machining of molded parts and countersinking

Tool connection:

- Modular interface

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

Product images and videos

Clamex P Connecter with Floating Aggregate

Cutting Honey Comb with Floating Aggregate

Dieser Inhalt eines Drittanbieters wird aufgrund Ihrer fehlenden Zustimmung zu Drittanbieter-Inhalten nicht angezeigt.

SOFT TOUCH PRO FUNCTION LINE or SOFT TOUCH ONE FUNCTION LINE

The SOFT TOUCH PRO FUNCTION LINE offers great flexibility for various applications. This is the result of the interchangeability of the sensing bell and the tool adapter, which means that different tools with different lengths can be used without the need for repeated tool calibration. The standard version of the probing aggregate is available with two sensing bells of different heights, which can accommodate different tool lengths. In addition, up to 82 different sensing devices are optionally available, which enable different applications depending on the material, sensing surface, tool width and height. Furthermore, specific customer requirements can be solved individually.

The adjustment range of the SOFT TOUCH PRO FUNCTION LINE can be flexibly set at a height of up to 10 mm. Particularly noteworthy is the quick and easy change of the probe bell, which is made possible by the practical bayonet lock. In contrast to competitor products, this change is carried out together with the tool change via the ET adapter without any problems, which increases the high flexibility of the probed applications on the CNC machine.

Despite the impressive technology in the SOFT TOUCH PRO FUNCTION LINE, the engineers at ATEMAG had good reason to develop another floating aggregate with similar specifications. The result is the SOFT TOUCH ONE FUNCTION LINE, which, unlike the PRO, does without the large number of touch probes but still offers the possibility of machining many standard applications. Thanks to the permanently integrated ER 32 tool spindle and the constant tracing bell, this probaing aggregate can be produced and offered more cost-effectively. Compared to the PRO, the ONE also offers a very large adjustment range of the tracer (up to 70 mm). The technology also promises high rigidity, which means that the ONE also ensures stable tool guidance and tool holding and extremely precise machining results. Both CNC aggregates have a fine adjustment for positioning the tracer and guarantee optimum machining results with the use of appropriate quality tools.

SOFT TOUCH PRO FUNCTION LINE:

- Offers great flexibility for different applications thanks to interchangeable sensing bells and tool adapters - different tools with different lengths can be used

- Two different sensing bells are available as standard to accommodate different tool lengths.

- Optional choice of up to 82 different tracers for specific applications.

- Adjustment range of up to 10 mm in height.

- Quick and easy change of the sensing bell by bayonet lock.

- High flexibility in adapting to different probing applications on CNC machines.

- Specific customer requirements can be solved individually.

- Cost-effective solutions for standard applications

- Integrated ER 32 tool spindle and the always constant tracer bell

- Offers a very large adjustment range of up to 70 mm.

- Permanently integrated ER 32 tool spindle and constant tracer bell.

- High rigidity for stable tool guidance and precise machining results.

- Well suited for applications where frequent tracer bell changes are not required.

The choice between these cnc aggregates depends on the planned applications and machining operations. The SOFT TOUCH ONE FUNCTION LINE is more cost-effective and ideal for consistent applications, while the SOFT TOUCH PRO FUNCTION LINE is more cost-effective for frequent touch bell changes. Both aggregates offer specific strengths and fulfill different requirements, so the right choice can save costs and time.

Your request for the SOFT TOUCH PRO FUNCTION LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use