SOFT TOUCH 3D FUNCTION LINE

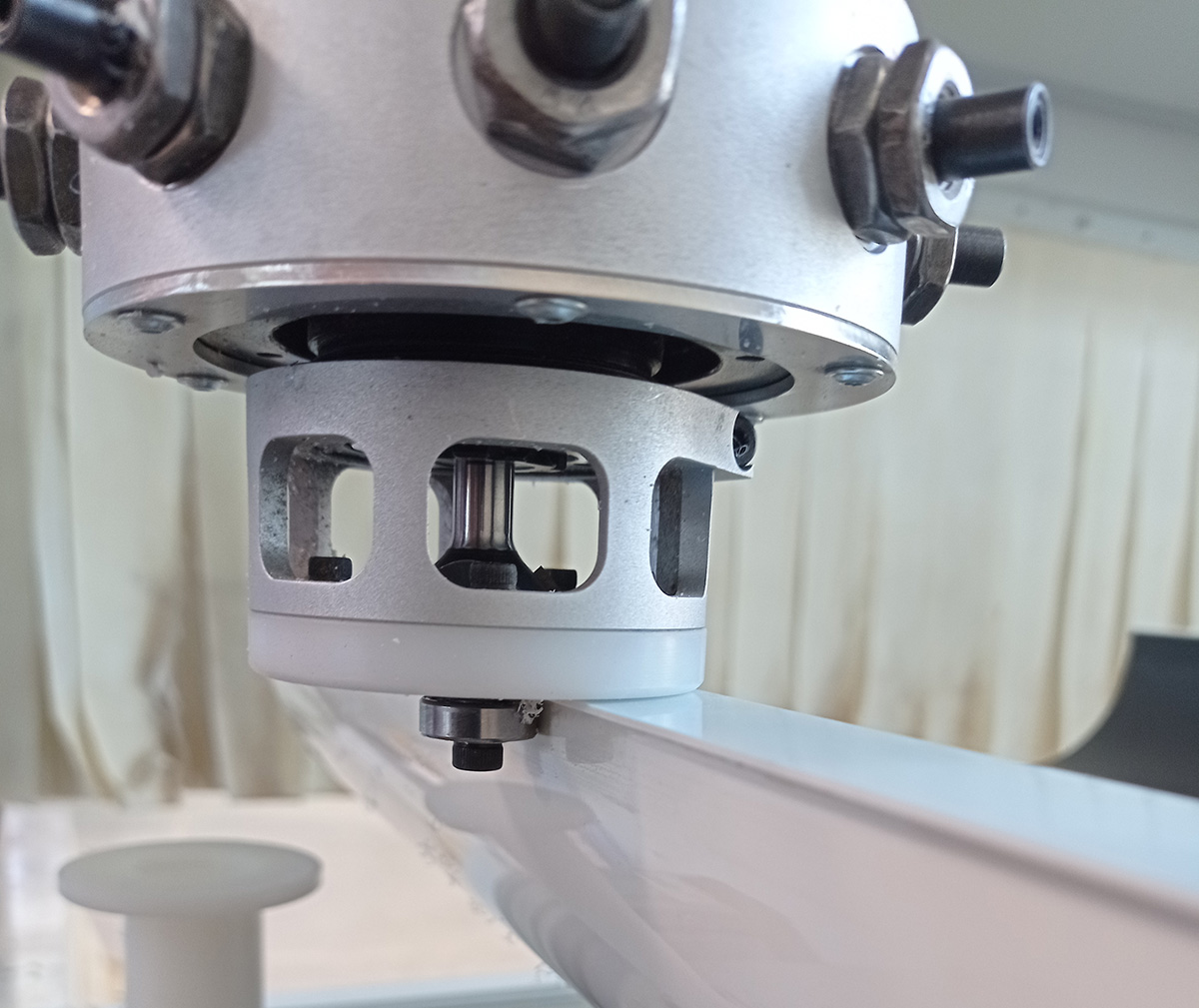

Floating aggregate for defined edge machining of

contoured parts on 5-axis machines or robot systems

Technical Data

| Machining options |  Milling |

|||

| Max. input speed: | 12.000 rpm | |||

| Max. output speed: | 12.000 rpm | |||

| Gear ratio: | 1 : 1 | |||

| Max. torque: | 10 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Floating capacity: | axial: 7,5 mm / radial 5 mm | |||

| Adjustment range: | 5 mm | |||

| Setting precision: | 0.01 mm | |||

| Probing direction: | axial and radial | |||

| Machining angle: | 0° | |||

| Adjustment range: | axial: 5 mm | |||

| Number of tool outputs: | 1 / fixed | |||

| Machining angle: | 0° | |||

| Lubrication: | Grease / Lifetime lubrication | |||

Product Information

Extension of the SOFT TOUCH 360° FUNCTION LINE floating aggregate with additional axial probing.

The SOFT TOUCH 3D FUNCTION LINE has been specially developed for edge processing of curved molded parts. The touch probe is a further development of the SOFT TOUCH 360° FUNCTION LINE. In addition to the radial probing capacity of 5 mm 360°around the tool spindle, the new aggregate has an additional axial probing capacity of 7.5 mm, which makes the probing circumference resemble a cylindrical solid.

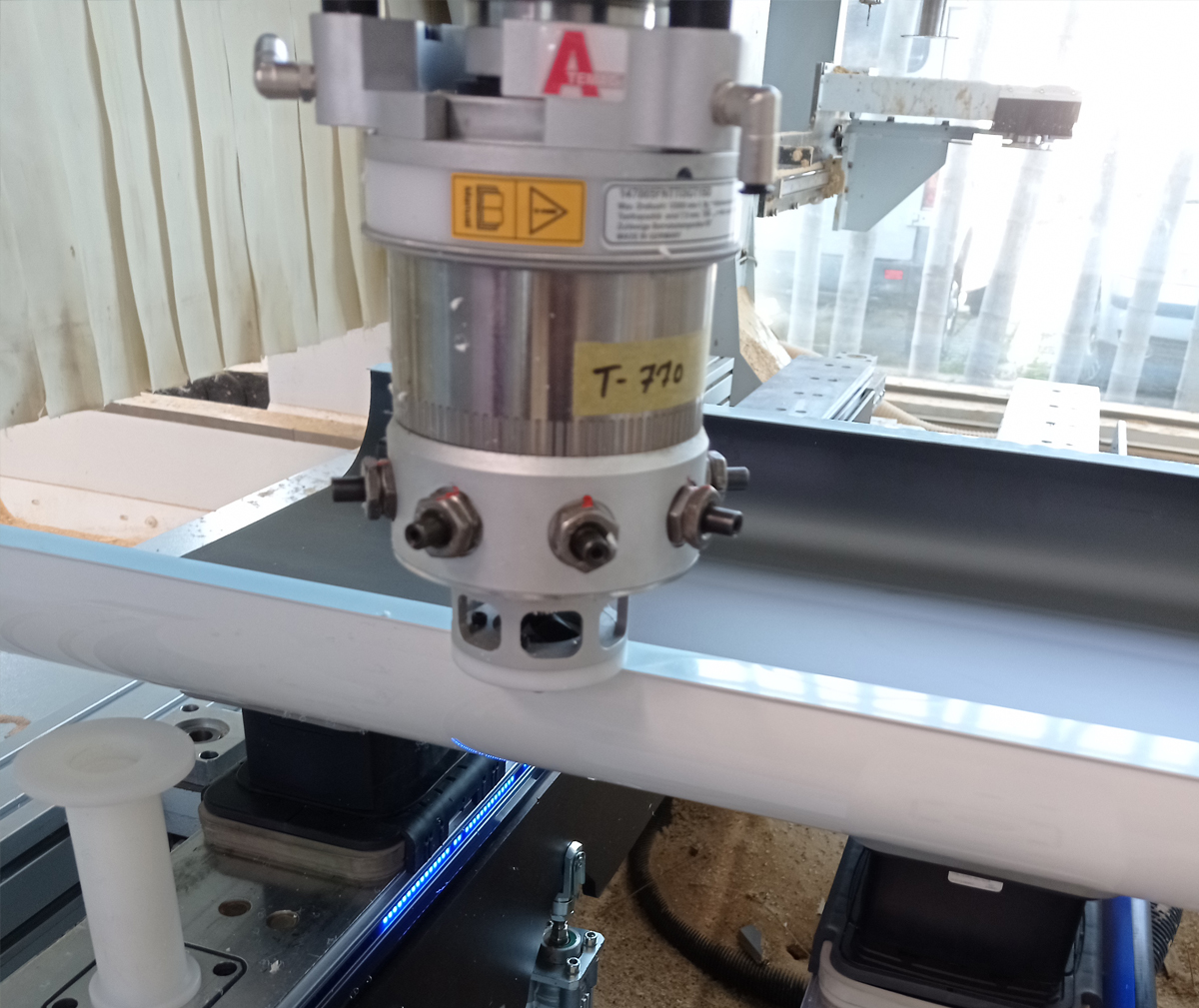

Defined edge processing on curved molded parts can be realized with the SOFT TOUCH 3D FUNCTION LINE in both CNC machines and robots. The unit is mostly used in five-axis machining centers in the industrial production of curved shapes, such as in musical instruments or in furniture production, for example, to mill edge plates flush. But also in industrial robot cells, the unit optimizes the production processes after the pressing process in end-of-arm solutions for edge processing of GRP and CFRP parts. While radial probing of the CNC aggregate for edge processing is performed via the start-up ring in front of the tool, axial probing is controlled via an individual probe element. The probing machining in radial and axial axes permanently compensates for thickness fluctuations and shape deviations, allowing complete processes in series production to be mapped automatically. This ensures a constant and defined machining quality on the component, the economic efficiency of the process and the quality of the workpiece.

Tool connections:

- ER 16 internal

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems.

The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

The SOFT TOUCH 3D Function Line floating aggregate is versatile and is also used for fiberglass leaf spring processing in the automotive industry. "The video shows how the aggregate, clamped as an end-of-arm solution in an industrial robot, mills the radius angle precisely and consistently on the edge of the fiberglass material for truck leaf springs, compensating for unevenness.

There are clear advantages in this application:

The floating aggregate extends the reach of the robot and enables vertical and horizontal milling. Machining with the probing aggregate is considerably faster, as time-consuming scanning processes can be dispensed with. In addition, manual reworking is no longer necessary, as the aggregate precisely and permanently compensates for thickness variations and shape deviations. The cost savings result from the fact that only the aggregate needs to be invested in. The purchase of expensive scanning systems and visual cam systems is unnecessary. In addition, the aggregate is easy to operate and can be used in CNC machines as well as in robots.

The SOFT TOUCH 3D Function Line can precisely process various materials such as wood, metal and plastic. When processing composite and lightweight materials, we work closely with the experts at C6 Tooling, who specialize in this market and offer comprehensive solutions and first-class support in this area."

Weitere Anwendungen in Anwendungen in Composite Bearbeitungen

Produktbilder und Videos

Your request for the SOFT TOUCH 3D FUNCTION LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use