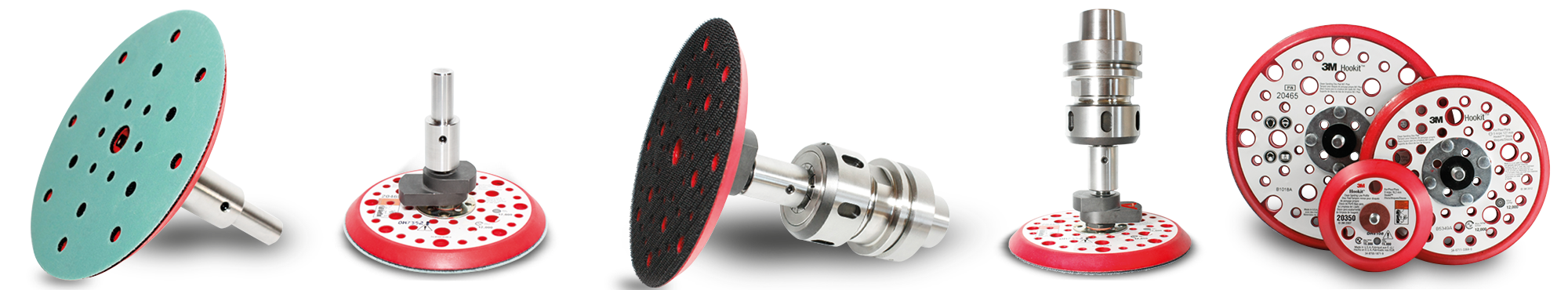

SOFT GRINDER SMART LINE

Eccentric sander for sanding or polishing work on CNC machines or robots on surfaces and edges – also suitable for free-form surfaces.

Technical Data

| Machining options | The SOFT GRINDER SMART LINE can be clamped in all angular aggregates units with ER 32 or ER 25 collet chuck interfaces. |

Grinding |

| Max. input speed: | 12.000 rpm | |

| Max. output speed: | 12.000 rpm | |

| Gear ratio: | 1 : 1 | |

| Permissible operating temperature: | max. 85°C | |

| Machining angle: | 0° | |

| Number of tool outputs: | 1 / fixed | |

| Max. floating capacity: | 4 mm | |

| Probing force: | 1,2 - 2,4 kg | |

| Eccentric stroke: | 5 | |

Product Information

Eccentric grinding unit for automated and full-surface sanding and polishing work

The SOFT GRINDER SMART LINE eccentric sanding unit enables automated full-surface sanding and polishing on CNC machines. The random orbital sander can be used to efficiently process convex or flat surfaces and edges. The eccentric sanding unit is simply clamped into an existing tool holder of the CNC machine or into a CNC unit. This allows sanding work to be carried out at different angles.

By using different sanding discs with different diameters and grit sizes, numerous options are available for surface processing in the machining center. The SOFT GRINDER SMART LINE enables final sanding, intermediate sanding or coarse sanding and is suitable for 3-axis, 4-axis and 5-axis machines. The sanding tool is suitable for a wide range of applications, including the chamfering of free forms.

The grinding pressure of the grinding tool is crucial for an optimum end result on the material to be processed. With the SOFT GRINDER SMART LINE, this can be adjusted using three different spring strengths, whereby the contact path of 4 mm is set using spring force. This enables the sanding of MDF and Swiss edges, the polishing of Corian elements and the processing of oiled woods or lacquers with intermediate sanding. Surface and edge sanding of veneered panels, solid surface materials and solid wood can also be carried out optimally. The sander is simply attached to an existing tool holder using a 16 mm shank. Alternatively, the random orbital sander is also available with a thermal chuck.

Machining capabilities:

- Sanding of edges and surfaces – rough, intermediate, and finish sanding ...

- Grinding at an angle (miters), e.g., Swiss edge

- Polishing of various materials, e.g., Corian

- ...

Materials: Veneered boards, solid wood, MDF, mineral materials, etc.

The sanding discs are available with diameters of

- ø76 mm

- ø125 mm

- ø150 mm available and can be exchanged.

Machine connection: The eccentric sanding unit is simply clamped into an existing tool holder or a CNC aggregate.

Swiss edge grinding on CNC machines

Beveled edges on tables or other workpieces are referred to as a "Swiss edge" or "Swiss profile". Sanding such edges can be a challenging task, especially when done manually with a hand sander. The difficulty with solid wood, for example, is to leave the edge unchanged..

The SOFT GRINDER SMART LINE offers the solution. Clamped directly in the tool holder of the CNC, the random orbital sander ensures fully automated processing with constant pressure.

Product images and videos

Your inquiry about the SOFT GRINDER SMART LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use