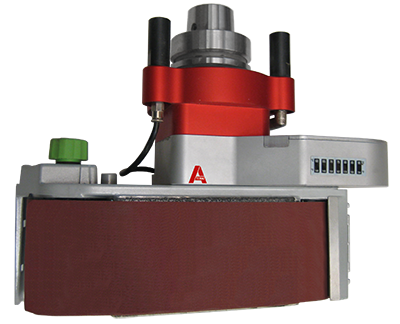

BELT SANDING AGGREGATE FUNCTION LINE

Efficient sanding of convex and flat edges.

Technical Data

| Machining options |  Grinding |

|||

| Max. input speed: | 7.560 rpm | |||

| Max. output speed: | 1.890 rpm | |||

| Gear ratio: | 4 : 1 | |||

| Max. torque: | 1 Nm | |||

| ermissible operating temperature: | max. 85°C | |||

| Positioning of torque arm with respect to tool: | 4 x 90° | |||

| Machining angle: | vertikal | |||

| Number of tool outputs: | 1 | |||

| Lubrication: | Grease / Lifetime lubrication | |||

CNC belt sanding unit for precise sanding of wooden edges

The ATEMAG CNC belt sanding unit is an innovative solution that integrates the functions of a belt sander directly into a CNC machine, enabling precise sanding of convex and flat wooden edges in CNC woodworking applications. The belt sanding unit is picked up via the tool changer and clamped into the spindle of the CNC machine. This CNC sanding unit offers the advantages of automated, efficient, and precise edge processing.

A sanding belt with dimensions 533 x 75 mm is used on the unit. Depending on the desired sanding result, different grit sizes of the sanding belt can be selected.

The CNC control system ensures precise control of the sanding process, which is particularly beneficial for the production of furniture, doors, or other wooden products.

The ATEMAG CNC belt sanding unit is a valuable addition to CNC machines used in furniture production, joinery, and other wood-processing industries, allowing manufacturers to achieve high-quality and aesthetically pleasing sanding results.

Product Information

Fully automated grinding of edges on CNC machines

Tool connection:

- Grinding belt 533x75 mm

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

Product images and videos

Your request for the BELT SANDING AGGREGATE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use