SOTTO FUNCTION LINE

Underside aggregate for routing and drilling on cantilever machines without board reclamping – Precise and efficient

Technical Data

| Machining options |  Drilling |

Milling |

||

| Max. input speed: | 15.000 rpm | |||

| Max. output speed: | 15.000 rpm | |||

| Gear ratio: | 1 : 1 | |||

| Max. torque: | 5 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Positioning of torque arm with respect to tool: | 4 x 90° | |||

| Machining angle: | 180° | |||

| Number of tool outputs: | 1 / fixed | |||

| Lubrication: | Grease / Lifetime lubrication | |||

CNC underfloor aggregate for processing on the underside of the panel

The SOTTO FUNCTION LINE is an innovative underfloor aggregate that has been specially developed for processing workpieces on the underside of CNC machines. The CNC aggregate is clamped into the spindle of the machine and diverts the tool output so that the tool plunges into the material from below.

Advantages of underfloor machining

- Time saving: Processing both sides of the workpiece panels in a single operation is possible without manual turning.

- Increased precision: Inaccuracies caused by manual turning of the plates are eliminated.

- Faster cycle times: Processing time and labor requirements are reduced.

Machining options on the underside of a material sheet

The underfloor aggregate enables a variety of drilling and milling operations on the underside of the workpiece, which can be carried out with a wide range of CNC tools. Blades and tools for marking drilling patterns can also be clamped in the aggregate's tool holder. The selection of the appropriate tool for underside machining depends on the type of material, the panel thickness and the specific application.

Processing from below for panels with thickness variations

For machining operations such as milling radii, chamfers and profiles on workpieces with varying thicknesses, the underfloor aggregate is equipped with a tracing device. This tracing device ensures that consistent and constant machining depths are also achieved on the underside of the workpiece.

Possible applications of the underfloor aggregate

Thanks to the possibility of using a wide variety of tools in the tool holder, numerous different applications can be carried out:

- Windows: Underfloor milling of sealing grooves

- Doors: Underfloor drilling (standard and cup hinge)

- Furniture + kitchens: Cup hinge drilling or milling for hinges

- Marking of drilling patterns

- Milling for fingerprint

- Milling of worktop connectors

- Milling of handle foils

- Milling of cup hinges and cup hinge hinges

- Drilling of handle foils

- Dowel holes

- Milling of hook-in connectors

- Milling of door rosettes

- Flush milling of rosettes

- Chamfering

- Traced radius processing

- Profile processing

Tool connections:

- ER 25 internal

- Weldon

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

Product images and videos

Your request for the SOTTO FUNCTION LINE

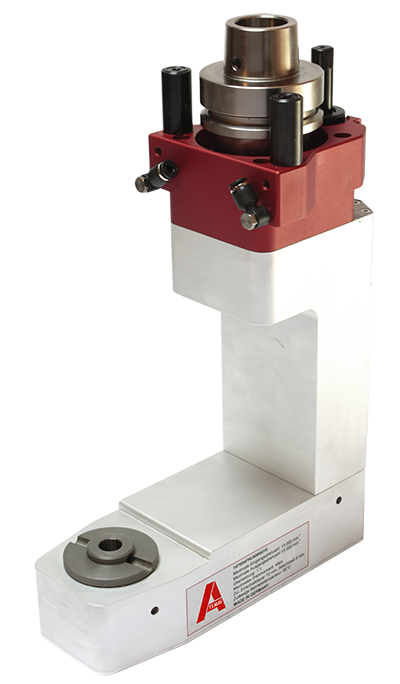

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use