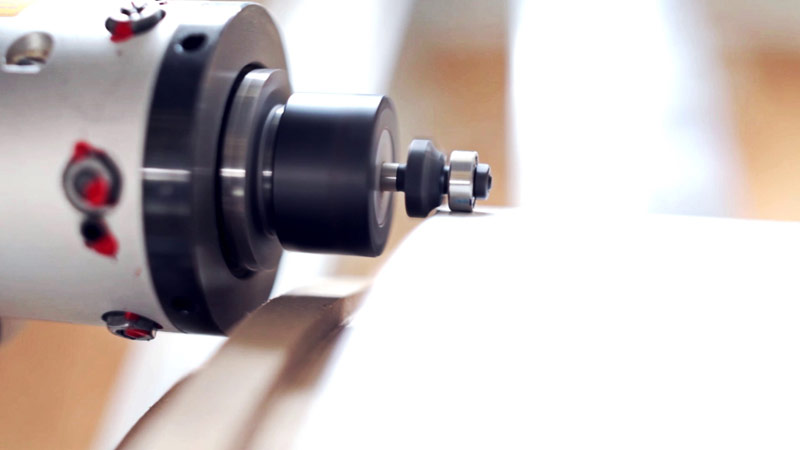

SOFT TOUCH 360° FUNCTION LINE

Floating aggregate for defined edge machining of contoured parts on 5-axis machines or robot systems

Technical Data

| Machining options |  Milling |

|||

| Max. input speed: | 12.000 rpm | |||

| Max. output speed: | 12.000 rpm | |||

| Gear ratio: | 1 : 1 | |||

| Max. torque: | 10 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Machining angle: | 0° | |||

| Number of tool outputs: | 1 / fixed | |||

| Lubrication: | Grease / Lifetime lubrication | |||

| Probing direction: | Radial | |||

| Floating capacity: | 5 mm | |||

Product Information

Copying function for compensating for shape and position tolerances in radial axis direction of molded parts, e.g., chamfers and radii, or for deburring.

Typical applications:

- Musical instruments: Edge machining of guitar bodies

- Furniture making: Edge machining of contoured shapes

Routing of glued-on edge banding flush with board on 5-axis machines - Industrial robot cells: End-of-arm solution for edge machining

of GFRP/CFRP parts after pressing - ...

Tool connections:

- Modular interface

- Other connections on request

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

SOFT TOUCH 360° DUO FUNCTION LINE

SOFT TOUCH 360° FUNCTION LINE with two tool outputs

Typical applications:

Furniture making and interior build-out: Routing of glued-on edge banding flush with board on 4-axis machines

A CNC floating aggregat fulfills the mechanical copying of the reference surface to be machined in order to carry out different machining operations and to compensate for a constant and defined machining depth despite stress inaccuracies and thickness variations.

The application areas of a floating aggregate are manifold. They range from milling V-grooves or decorative grooves to classic edge machining such as contour and radius milling and drilling with a defined depth to milling recesses, such as for worktops.

If the machining of curved moldings on 5-axis systems or robotic systems is required, the SOFT TOUCH 360° FUNCTION LINE floating aggregate is shortlisted. One application example is the contour machining of a curved instrument body such as that of a guitar. This is subject to three-dimensional variations due to the manufacturing process.

The technical finesse of the aggregate is the "floating" tool spindle. Controlled by a thrust ring in the X/Z direction, this allows contour variations of up to ± 5 mm to be compensated. The floating aggregate moves completely freely in the X/Z plane, probing is implemented in the plane in ALL directions at right angles to the machining axis, so that the contour is scanned without errors and individually machined with a milling cutter. Contour variations are thus no longer perceived by the observer. An ideal machining result can be achieved even with relatively small contour tools and, at the same time, costly reworking can be avoided.

The MONO version of the aggregate, which has one tool output in the vertical direction, is joined by the SOFT TOUCH 360° DUO FUNCTION LINE. The aggregate has two tool outputs in the horizontal machining direction, which is an immense advantage in tight spaces and extends the machining possibilities. Likewise, with this aggregate solution, tool changes can be saved if several applications with different tools are required.

A typical application of both aggregates is the milling of radii or contours on the panel side. Here, both aggregates realize the machining of the top and bottom edges and their intervening end faces in a single operation. In addition, overhangs of glued-on edges on shaped workpieces can also be milled flush.

Product images and videos

Dieser Inhalt eines Drittanbieters wird aufgrund Ihrer fehlenden Zustimmung zu Drittanbieter-Inhalten nicht angezeigt.

Your request for the SOFT TOUCH 360° FUNCTION LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use