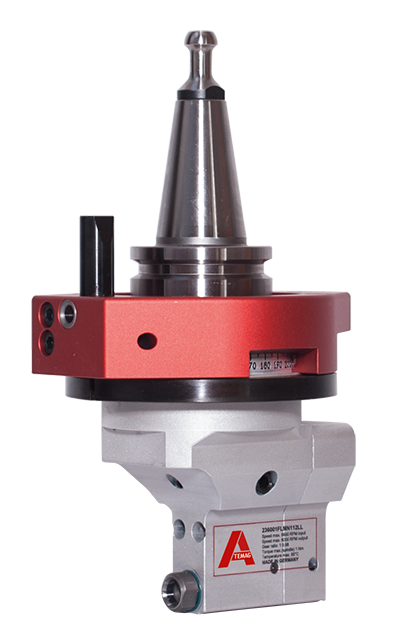

MONO LOW LEVEL FUNCTION LINE

Drilling on nesting machine - nesting aggregate for efficient drilling of holes for dowel joints in body elements thanks to especially compact design

Technical Data

| Machining options |  Drilling |

|||

| Max. input speed: | 6.800 rpm | |||

| Max. output speed: | 6.000 rpm | |||

| Gear ratio: | 1 : 0,88 | |||

| Max. torque: | 1 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Positioning of torque arm with respect to tool: | 360° | |||

| Machining angle: | 90° | |||

| Number of tool outputs: | 1 / fixed | |||

| Lubrication: | Grease / Lifetime lubrication | |||

Efficient production processes on nesting machines with particularly compact drilling unit

Panel materials made of wood, particleboard and MDF can be optimally formatted in nesting machines. In the so-called nesting process, panel sizes are separated in a space-saving manner, minimizing material consumption and reducing production time. After formatting the workpieces, additional processing methods are possible. Nesting machines can perform complex machining operations such as drilling, milling, recessing and other cutting operations using various tools.

Due to the flatbed machine table, horizontal machining is a challenge here. The use of an angle aggregate expands the functionality and versatility of CNC machining. An angle drilling aggregate specially developed for nesting machines is the MONO LOW LEVEL FUNCTION LINE from ATEMAG. The compact angle head enables precise drilling of dowel holes in edges, even for workpieces with low heights. The aggregate can precisely drill holes with 6 mm and 8 mm diameters for panel thicknesses from 16 mm and reduces the need for manual labor, which in turn significantly optimizes production processes.

Machining capabilities: Drilling of dowel holes of diameter 6 or 8 mm in boards of thickness 16 mm or greater.

Typical applications: Furniture production on nesting machines.

Tool connection:

- M8 with Ø9H5 centering hole

Machine connection:

ATEMAG aggregates are used on all CNC machines and robot systems. The machine connection is precisely matched to the technical requirements of the CNC machine or robot.

Your request for the MONO LOW LEVEL FUNCTION LINE

NEW:

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use