SOLUTIONS FOR CLAMEX CONNECTORS

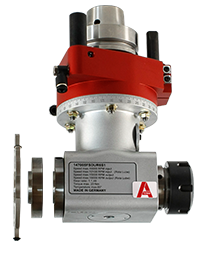

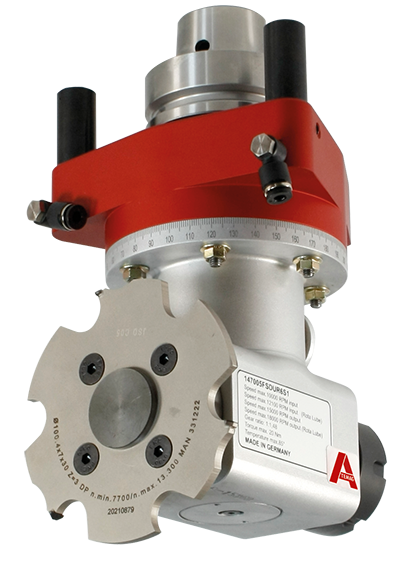

Vertical Clamex groove routing in surfaces with gentle machining using a standard ATEMAG aggregate – all-in-one system solution

Technical Data

| Machining options |  Drilling Drilling |

Milling Milling |

||

| Max. input speed: | max. 10.000 rpm with Rota Lube: max. 12.100 rpm |

|||

| Max. output speed: | max. 15.000 rpm with Rota Lube: max. 18.000 rpm |

|||

| Gear ratio: | 1 : 1,48 | |||

| Max. torque: | 20 Nm | |||

| Permissible operating temperature: | max. 85°C | |||

| Positioning of torque arm with respect to tool: | 360° | |||

| Machining angle: | 90° | |||

| Number of tool outputs: | 2 /fix | |||

| Lubrication: | Grease / Rota Lube – Lifetime lubrication | |||

| Suitable for: |  |

|||

Product Information

The MONO, DUO, and QUATTRO standard aggregates allow the Clamex connector to be positioned at any point on the board thanks to the vertical position of the Clamex groove side milling cutter and the spindle design of the aggregate. For diagonal positioning of the groove, the MONO FIX FUNCTION LINE (fixed angle) or the VARIO (variable angle) can be used. The grooving cutter tool of the respective aggregate is plunged into the surface during machining and moved sideways at a precise depth.

Floating Aggregate for Clamex Connectors

Grooves for Clamex connectors can also be routed into edges and surfaces of workpieces that have thickness fluctuations. The SOFT TOUCH PRO FUNCTION LINE, which is equipped with a special probe, is suitable for this type of machining.

Clamex P Connector with Floting Aggregate

Mill the Clamex groove - presize and automated - with a standard unit from ATEMAG

The milling of large quantities of Clamex connector pockets is time-saving and cost-reducing for industrial production with a CNC unit from ATEMAG - with the integration of the CNC unit in your machining center, the milling of connector pockets for Clamex is simplified many times over.

In the process, the groove milling tool of the aggregate is machined into the machining surface and laterally shifted at the exact depth. The groove for the Lamello Clamex P connectors can be machined with various aggregates from ATEMAG, whether vertically in the surface, at the edge of the workpiece or at a specific angle. Depending on the available space in the machining center, the axis of the machine and the angle of the milling, we will be happy to offer you the appropriate aggregate that you can use optimally for milling the Lamello P-System groove.

System solution for Lamello Clamex Groove.

Benefit from the use of the DUO FUNCTION LINE for milling the Clamex groove.

- Automated Clamex connector groove milling on all common CNC machining centers and robot systems.

- Increased flexibility and efficiency of the CNC machining center (also 5-axis technology)

- Vertical milling in the surface for Lamello P systems

Clamex P profile groove in the surface using the angle aggregate DUO SMART LINE.

This video shows how the profile groove for Clamex P connectors is performed in the surface using the DUO SMART LINE angle unit in a 3-axis machine. The angle unit can mill the profile groove in the surface in two directions by rotating the angle head in the cam box of CNC machine by 90°.

Clamex profile groove milling provides an efficient method for making joints in wood-based materials. It allows easy assembly and disassembly of the elements. This milling creates a special profile groove that is perfectly matched to the Clamex P fasteners.

Clamex P profile groove in the surfaces.

Product images and videos

Your request for the Solutions for Clamex milling with one aggregate

NEW:

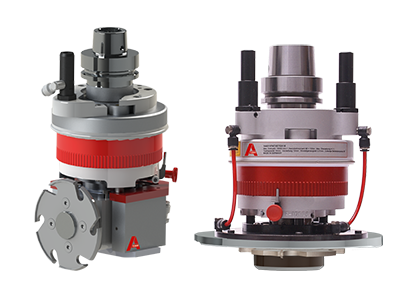

Universal Assembly and Adjustment Device (HSK 63)

The universal assembly and adjustment device (HSK 63) enables the safe clamping of all types of aggregates outside the machine – regardless of their design or machine interface.

In addition to maintenance work on the aggregate, shank tools or complete tool sets can be reliably assembled and adjusted – whether inside the aggregate, in tool holders, or on milling arbors – quickly, precisely, and safely.

Thanks to its compatibility with all common machine connections, the device offers flexible application possibilities, regardless of the position and number of locking or support pins on the aggregate. Even tool holders with nesting turbines fit effortlessly.

Whether angle adjustments on swivel aggregates, setting tool positions on sensing aggregates, or tool changes on multi-spindle drilling heads – our assembly and adjustment device is THE essential tool for every workshop equipped with CNC machinery.

Key Features:

- Easy handling of aggregates with various designs

- Suitable for all common machine interfaces

- Secure clamping and precise alignment of tools

- Universally applicable for assembly, maintenance, and production

- Robust design for long-term, continuous use